“It’s how much?” If you’ve started shopping for new kitchen countertops, that’s a phrase you’ve likely muttered under your breath. You see a beautiful slab of granite or quartz online advertised at $50 per square foot, but when the initial quotes roll in, the final figure is nearly double. It’s a frustratingly common experience for homeowners, leaving you feeling confused and wondering where all the extra charges are coming from. The truth is, the price of the stone itself is just one piece of a much larger puzzle.

Welcome to your definitive cost guide for 2025–2026. Remodeling in the Sunshine State has its own unique rhythm. Between fluctuating labor rates that can vary from the Panhandle to the Keys, post-inflation supply chain wrinkles, and the ever-present demand for durable, beautiful materials that can withstand our humid climate, Florida homeowners face a distinct set of challenges. This guide is designed to cut through the noise. We will break down the true, all-in installed cost of quartz and granite countertops, line by line, so you can build a realistic budget, understand your quote, and invest in your home with confidence.

The Bottom Line: Installed Countertop Costs in Florida (2025–2026)

Let’s get straight to the numbers. When you receive a quote from a fabricator, it should be for the “installed” price. This is a bundled cost that includes the material, fabrication, and installation labor. It’s the most reliable figure to use for budgeting.

Based on current market analysis, material costs, and regional labor trends across Florida for 2025–2026, here are the typical installed price ranges you can expect:

- Installed Quartz Countertops: Expect to pay between $85 and $190 per square foot. The vast majority of projects fall into the $100 to $150 range for high-quality, mid-grade materials with standard fabrication.

- Installed Granite Countertops: Expect to pay between $80 and $180 per square foot. While entry-level granite can sometimes be slightly more affordable than basic quartz, exotic, high-end granite slabs can easily surpass the cost of premium quartz.

These figures are a strong starting point, but why the wide range? It comes down to the specific stone you choose, the complexity of your kitchen layout, and the details of the fabrication process.

Price Comparison Table: Florida Installed Countertop Costs (2025–2026)

To help you visualize your budget, here is a more detailed breakdown of costs by tier. Tiers are determined by factors like rarity, brand, complexity of the pattern (for quartz), and mineral composition (for granite).

| Material Tier | Description | Installed Cost per Sq. Ft. (Florida Estimate) |

| Basic Quartz | Solid colors (white, gray, beige), simple speckles. Often from lesser-known or builder-grade brands. | $85 – $110 |

| Mid-Range Quartz | More complex patterns, subtle veining, popular brand names (e.g., Silestone, Cambria entry-level). | $110 – $150 |

| Premium Quartz | Intricate, marble-like veining, dramatic patterns, top-tier brands, book-matched slabs. | $150 – $190+ |

| Basic Granite | Common, consistent patterns (e.g., Ubatuba, New Caledonia, Santa Cecilia). Readily available. | $80 – $105 |

| Mid-Range Granite | More color variation, visible movement, less common patterns (e.g., Giallo Ornamental, Absolute Black). | $105 – $145 |

| Premium Granite | Exotic, rare slabs with unique colors and dramatic, flowing patterns (e.g., Blue Bahia, Fusion Wow). | $145 – $180+ |

What’s Actually in Your Countertop Quote? A Line-by-Line Explanation

A professional quote is more than just a price; it’s a statement of work. Understanding its components is key to comparing offers and ensuring there are no surprises. Here’s what you should see itemized or bundled into your installed price.

- The Stone Slab: This is the base cost of the material itself. For granite, this is dictated by the rarity and origin of the stone. For quartz, it’s driven by the brand, the complexity of the design, and the manufacturing process. You will typically need to purchase the full slab, even if your project doesn’t use it all.

- Fabrication: This is where the magic—and a significant portion of the cost—happens. Fabrication is the highly skilled process of transforming a raw slab into a custom countertop. It includes:

- Templating: Creating a precise digital or physical model of your cabinets to ensure a perfect fit.

- Cutting: Using advanced machinery like CNC saws and waterjets to cut the slab to the exact dimensions of your template.

- Edge Profiles: Finishing the edges of the stone. A simple, squared-off “eased” edge is standard. More decorative edges like bullnose, ogee, or waterfall will add to the cost.

- Cutouts: Creating openings for your sink (undermount is more expensive than drop-in), cooktop, faucets, and electrical outlets. Each cutout requires precision work and adds to the labor cost.

- Backsplash Returns: This refers to the short, 4-inch “lip” of countertop material that runs up the wall. While once standard, many modern designs skip this in favor of a full tile backsplash. If you want it, it will be calculated as part of your total square footage.

- Installation: This covers the labor for the trained, insured crew to transport the fabricated pieces to your home, lift them into place, level them perfectly, create discreet seams where necessary, and secure them to your cabinets. This is physically demanding, precision work you should never attempt to DIY.

- Sealing (for Granite): While quartz is non-porous and doesn’t require sealing, all-natural granite does. Your fabricator should apply a professional-grade sealant upon installation to protect it from stains. This is almost always included in the price.

What Changes Your Quote? The Ultimate Cost Factor Checklist

Why did your neighbor’s kitchen cost $1,000 less than your quote for the same square footage? The answer lies in the details. Use this checklist to understand what drives your costs up or down.

- [ ] Stone Origin & Tier: An exotic granite from a single quarry in Brazil will cost far more than a common granite from India. Similarly, a premium Cambria quartz with intricate veining costs more than a simple white builder-grade quartz.

- [ ] Slab Thickness: The industry standard is 3cm (about 1 1/4 inches). Some companies offer 2cm slabs, which are slightly cheaper but may require a plywood underlayment and look less substantial.

- [ ] Layout Complexity: A simple galley kitchen with one straight run is far easier (and cheaper) to fabricate than a U-shaped kitchen with multiple corners, seams, and custom angles.

- [ ] Number of Cutouts: The base price usually includes one sink cutout. Each additional cutout for a prep sink, cooktop, or outlet adds cost. Undermount sink cutouts are more labor-intensive than drop-in sink cutouts.

- [ ] Edge Profile: A standard eased edge is included. A decorative ogee or a complex mitered edge for a waterfall island will significantly increase fabrication costs.

- [ ] Your Local Market: Labor rates in Miami or Naples are often higher than in Jacksonville or the Panhandle. Get multiple quotes to understand the going rate in your specific ZIP code.

- [ ] The Fabricator’s Reputation & Technology: A top-tier fabricator with a state-of-the-art digital templating system and CNC machinery may charge more, but they often deliver a superior, more precise final product.

Don’t Forget! Hidden & Overlooked Countertop Costs

These are the items that often don’t appear in the initial “per square foot” price but are necessary for the project to be completed. Always ask your fabricator if these are included in their quote or are separate line items.

- Tear-Out & Disposal of Old Countertops: Most companies offer this as a service for an additional fee, typically ranging from $200 to $500, depending on the material (tile is much harder to remove than laminate).

- Plumbing Reconnection: The countertop installers are not licensed plumbers. You will need to hire a separate plumber to disconnect your sink and faucet before the old tops are removed and reconnect them after the new ones are in. This can cost anywhere from $250 to $500.

- Delivery Fees: Especially if you live in a more remote part of Florida, a trip charge may be added to the final invoice.

- Structural Support: If you’re installing a heavy stone on an island with a large overhang, you may need to add corbels or steel support brackets, which is an additional material and labor cost.

A Note on the Florida Market: Local Factors to Consider

Living in Florida brings a few unique considerations to your countertop project:

- Humidity & Materials: Both quartz and granite are excellent choices for Florida’s humid environment as they are resistant to moisture and inhibit the growth of mold and mildew. This is a key reason for their popularity in the state.

- Hurricane Season & Supply Chains: While less of an issue than in previous years, be aware that project timelines can sometimes be extended during peak hurricane season (June-November) if port activity or ground transportation is disrupted. It’s wise to build a little buffer into your renovation schedule.

- Regional Labor Trends: Florida’s construction market is booming. High demand, especially in rapidly growing areas of Central and Southwest Florida, can lead to longer wait times and firmer pricing from top-rated installers. Booking your fabricator several weeks in advance is recommended.

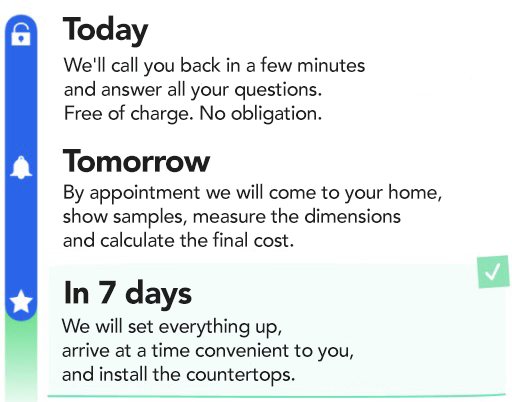

Your Next Step: Get a Real-Time Estimate from a Florida Pro

This guide provides a comprehensive overview of what you can expect to pay for quartz or granite countertops in Florida for 2025–2026. However, the only way to know the true cost for your kitchen is to get a custom quote based on your unique layout, material choice, and location.

A reputable fabricator will provide a detailed, itemized estimate that accounts for everything discussed here. Don’t settle for a simple square foot number scribbled on a business card. Demand a professional quote that empowers you to make an informed decision for your home.