In the world of home design, the kitchen countertop is often the centerpiece of the renovation. For the past two decades, engineered quartz has reigned supreme, beloved for its durability, consistency, and vast color options. However, a new topic has entered the conversation, one that moves beyond aesthetics and scratch resistance: engineered stone safety and the presence of crystalline silica.

Recent headlines regarding silica bans in Australia and increased regulatory focus in the United States have left many homeowners confused. You may be asking: Is the surface in my kitchen safe? Should I be worried about the air quality in my home? What does “low-silica” actually mean?

It is vital to approach this topic with facts rather than fear. The short answer is that installed quartz countertops are safe for residents. The risks associated with silica are primarily an occupational hazard—a danger faced by the professionals who cut, grind, and polish the stone, not by the families who cook on it.

However, as a conscientious consumer, understanding the shift toward low silica quartz countertops and knowing how to hire a safety-compliant fabricator allows you to make choices that are ethical, sustainable, and informed. This comprehensive guide breaks down the science of silica dust countertops, explains the industry’s pivot to new materials, and empowers you to navigate the market with confidence.

1. The Core Issue: What is Silica and Why Does It Matter?

To understand the current regulatory landscape, we must first understand the material itself.

What is Crystalline Silica?

Silica (silicon dioxide) is one of the most common minerals on Earth’s crust. It is a primary component of sand, granite, sandstone, and clay. In its solid, natural form, it is harmless. You walk on it at the beach; you handle it when you garden.

The health risk arises only when crystalline silica is disturbed mechanically—crushed, drilled, ground, or cut. This process creates microscopic dust particles known as respirable crystalline silica (RCS). These particles are roughly 100 times smaller than a grain of sand, invisible to the naked eye, and capable of penetrating deep into the lungs.

The Crucial Distinction: Occupational Hazard vs. Household Safety

This is the single most important concept for homeowners to grasp. The danger of silica is tied strictly to the process of modification, not the existence of the material.

- The Hazard (Fabrication): When a worker cuts a slab of high-silica stone without proper safety controls (like water suppression or industrial vacuums), millions of silica particles become airborne. If inhaled over long periods without protection, this dust can scar lung tissue, leading to an incurable condition called silicosis. This is why the issue is classified as an occupational health crisis.

- The Safety (Installation): Once the countertop is cut, polished, installed in your kitchen, and wiped clean, the silica is trapped inside the resin binding agent. It is chemically bound and solid. There is no “off-gassing” of silica dust. Chopping vegetables, kneading dough, setting down hot plates, or even chipping the edge of the counter does not generate respirable dust in any meaningful or dangerous quantity.

For the homeowner, the finished product is inert. The global drive for low silica quartz countertops is about protecting the workforce that builds our homes, ensuring that the people who create our kitchens can do so without compromising their health.

2. The Global Context: Why Are You Hearing About This Now?

If silica has always been in stone—granite, for example, has contained silica for millions of years—why is it suddenly a headline news story?

The Rise of Engineered Stone

The urgency stems from the explosion in popularity of engineered quartz. Twenty years ago, quartz was a niche product. Today, it dominates the market. Traditional engineered quartz is composed of approximately 90–93% crushed natural quartz aggregates bound with resin. Because natural quartz is pure silica, these slabs often have a total silica content exceeding 90%. By comparison, natural granite typically contains 25% to 45% silica.

The high concentration in traditional engineered stone, combined with its massive market volume, meant that fabricators were cutting more high-silica material than ever before. This increased exposure load revealed vulnerabilities in safety enforcement in various parts of the world.

The Australian Ban

In 2024, Australia became the first country to implement a comprehensive ban on the manufacture, supply, and installation of engineered stone with high silica content. This decision was driven by a specific need to curb rising occupational health rates within the Australian trade. While this was a drastic regulatory step specific to that region’s legal framework, it sent ripples through the global supply chain, prompting manufacturers worldwide to accelerate the development of alternative formulations.

The United States Approach: Control and Compliance

In the United States, the approach has generally been one of strict enforcement and updated safety standards rather than outright product bans. Agencies like OSHA (Occupational Safety and Health Administration) and state bodies (such as Cal/OSHA in California) have doubled down on enforcing “Table 1” regulations.

The U.S. perspective emphasizes that silica risks are manageable with the right technology and protocols. The focus is on “Wet Methods”—using water during cutting to trap dust before it becomes airborne—and proper ventilation. However, the market is listening to the global conversation. Major quartz manufacturers selling in the U.S. are voluntarily transitioning their portfolios toward reduced silica formulas to future-proof their products and align with global corporate responsibility goals.

3. Understanding “Low-Silica” Quartz

As the industry pivots, you will see new terms on sample boards in showrooms. But what constitutes “low silica”?

While there is no single, globally mandated definition, the industry generally categorizes materials as follows:

- Traditional High Silica Quartz: > 85% crystalline silica. (The industry standard for decades).

- Reduced Silica: 40% – 80% crystalline silica.

- Low Silica: < 40% crystalline silica.

- Ultra-Low / Mineral Surfaces: < 15% crystalline silica.

How Is It Made?

To lower the silica content without sacrificing the hardness and durability that makes quartz popular, manufacturers must change the “recipe.” They substitute the crushed quartz aggregate with other durable minerals. Common substitutes include:

- Recycled Glass: Often the primary substitute. High-quality recycled glass is crushed to act as the aggregate. It offers high durability and adds an eco-friendly component to the slab.

- Feldspar: A natural mineral commonly found in granite that is harder than glass but contains less free silica.

- Porcelain Clays: Utilizing ceramic technologies to fortify the slab.

- Sintered Minerals: Some new “hybrid” surfaces use extreme heat to bond minerals (sintering) alongside resins, creating a hybrid between porcelain and quartz.

Does It Look or Perform Differently?

For the homeowner, the difference is virtually imperceptible. Low silica quartz countertops retain the non-porous, stain-resistant, and hard-wearing properties of traditional quartz.

- Aesthetics: The visual array—from realistic marble veining to solid modern white and gray—remains achievable with these new mixtures.

- Maintenance: The care routine (soap and water, avoiding harsh chemicals) remains identical.

- Durability: New formulations often boast equal or improved flexural strength compared to old high-silica versions.

4. The Homeowner’s Role: Responsible Hiring

While you cannot control the chemical composition of a slab or the regulations of the industry, you have immense power in choosing who fabricates and installs your countertops. By hiring a professional, compliant fabricator, you ensure that your renovation supports a safe working environment.

Price is often the deciding factor for renovations, but a significantly lower bid sometimes comes at the cost of safety equipment. When interviewing potential fabricators, do not be afraid to ask specific questions about their safety practices. A reputable shop will be proud of their safety culture.

The “Safety Audit” Questions for Homeowners

1. “Do you use wet-cutting methods for all stone processing?”

- Why ask: Wet cutting (using saws and polishers that spray water constantly) is the single most effective way to suppress silica dust. The water captures the dust particles, turning them into harmless sludge that can be disposed of safely.

- Red Flag: If a fabricator mentions “dry grinding” or cutting inside your home without water, this is a major safety violation.

2. “How do you handle on-site modifications?”

- Why ask: Ideally, all cutting happens in the factory. However, walls are rarely straight, and sometimes a backsplash needs a trim during installation.

- The Right Answer: They should use tools equipped with HEPA-filtered dust extractors or, preferably, take the piece outside to cut it using wet methods. They should never dry-cut stone inside your kitchen without high-efficiency vacuum attachments.

3. “Is your shop compliant with OSHA’s silica standards?”

- Why ask: This signals that you are an informed consumer. You are looking for confirmation that they follow “Table 1” of the OSHA standards, which outlines the required engineering controls for silica.

4. “Do you have air monitoring and air filtration in your shop?”

- The Right Answer: High-quality shops invest in massive air filtration systems (like giant air purifiers) that scrub the air of the factory floor, protecting workers even when they aren’t cutting.

5. “Are you a member of the Natural Stone Institute (NSI) or ISFA?”

- Why ask: Membership in professional associations (Natural Stone Institute or International Surface Fabricators Association) often indicates a commitment to ongoing education, accreditation, and industry best practices regarding engineered stone safety.

By asking these questions, you create demand for safety. You signal to the market that homeowners value human health as much as they value the price per square foot.

5. Exploring Material Alternatives and Tradeoffs

If you prefer to move away from traditional quartz entirely, the market is full of excellent alternatives. Each comes with its own silica profile and set of pros and cons.

A. Porcelain and Sintered Stone

These materials are rapidly gaining popularity as the primary low-silica alternative to quartz. They are made from clays and minerals baked at incredibly high temperatures (sintering), essentially creating man-made rock.

- Silica Safety: Generally very low (often < 15% or effectively zero free crystalline silica depending on the brand).

- Pros: Extreme heat resistance (you can put a hot pan directly on it), UV resistant (great for outdoor kitchens), completely scratch-proof.

- Cons: The material is under high tension. It can be brittle during fabrication, leading to higher labor costs and potential for chipping at the edges if hit with a heavy pot. The pattern is often printed on the surface, so the “veining” may not go all the way through the edge (though “through-body” technology is improving).

B. Natural Granite

- Silica Safety: Varies by stone type, typically 25% to 45% (significantly lower than traditional quartz, but not zero). Because it is natural, the silica is often bound differently than in engineered aggregates.

- Pros: Each slab is unique; high heat resistance; repairs are often easier than on engineered stone. It has a timeless appeal.

- Cons: It is porous and requires sealing (though modern sealers last years); natural variations mean you can’t guarantee a specific look from a small sample.

C. Natural Marble and Limestone

- Silica Safety: Very low (often < 5%). Marble is primarily Calcium Carbonate, not silica. It is one of the safest stones to fabricate regarding silicosis risk.

- Pros: The classic, luxury aesthetic that engineered stone tries to mimic. It adds value to a home.

- Cons: Very soft and porous. It will etch (dull) instantly with acids like lemon juice, tomato sauce, or vinegar. It stains easily and creates a “living finish” (patina) that not all homeowners appreciate.

D. Solid Surface (e.g., Corian)

- Silica Safety: Zero. These are acrylic-based materials containing minerals like alumina trihydrate (ATH).

- Pros: Seamless integration (no grout lines), repairable (scratches can be sanded out), warm to the touch, can be molded into complex shapes.

- Cons: Softer than stone (scratches easily), not heat resistant (hot pans will melt or scorch it). It lacks the “depth” and visual complexity of stone.

6. Myths vs. Facts: Clearing the Air

There is significant misinformation circulating on social media regarding silica dust countertops. Let’s set the record straight to alleviate unnecessary anxiety.

Myth: “If my quartz countertop chips, silica dust will poison my food.”

Fact: A chip in a quartz countertop releases a negligible amount of dust, most of which settles immediately. There is no continuous release of dust. The risk of silicosis requires chronic, high-volume inhalation of fine dust over time (years of occupational exposure), not incidental ingestion or minimal exposure from a chipped edge.

Myth: “I have to rip out my old quartz countertops because they are unsafe.”

Fact: Absolutely not. Installed quartz is completely safe. Removing it unnecessarily actually creates more waste and potential dust (during demolition) than leaving it in place. Enjoy your current kitchen; it is not harming you.

Myth: “Natural stone has no silica, so it’s always the safer choice.”

Fact: Most natural stones contain some silica. Sandstone and quartzite, for example, can have very high silica content, sometimes rivaling engineered quartz. Granite has moderate levels. Marble has very low levels. “Natural” does not automatically mean “silica-free,” though natural stone fabrication generally produces larger, heavier dust particles that settle faster than the fine dust from engineered stone.

Myth: “Low-silica quartz is weaker and prone to cracking.”

Fact: This was a concern with early prototypes, but major manufacturers have spent years refining the chemistry. Modern low-silica variants use high-strength mineral bonds and vacuum-vibro-compression technologies that meet the same durability standards (Mohs hardness, flexural strength) as traditional quartz.

7. Frequently Asked Questions

Q1: How do I know if a quartz sample is “low silica”?

Manufacturers are beginning to label these slabs clearly, often with terms like “Low Silica,” “Mineral Surface,” “Sustainable Series,” or specific eco-labels. If it isn’t marked, ask your fabricator for the “Safety Data Sheet” (SDS) or the technical specifications of that specific color line. The SDS will list the percentage of Quartz/Silica.

Q2: Is low-silica quartz more expensive?

Currently, there may be a slight premium for the newest mineral technologies due to R&D and production changes. However, as the industry standardizes and production scales up, prices are expected to align with traditional quartz. High-end traditional quartz and low-silica options are currently comparable in price.

Q3: Can I repair a low-silica quartz countertop if it cracks?

Yes. Professional stone restoration experts use UV-cured resins and epoxies to repair chips and cracks. The process is identical to repairing traditional quartz or granite. The change in mineral composition does not affect repairability.

Q4: Does the silica risk affect the installation day at my house?

Installation is mostly a clean process involving lifting, leveling, and gluing. However, if the installers need to trim the backsplash or drill a faucet hole on-site, ask that they use a vacuum-assisted tool. This is standard best practice not just for silica, but to keep fine dust out of your drawer glides and electronics.

Q5: Why don’t we just ban silica everywhere?

Silica is one of the most abundant minerals on the planet. It is essential in the production of concrete, bricks, glass, ceramics, computer chips, and even toothpaste. Banning it entirely is impossible and impractical. The goal of regulations is to manage the dust it creates during industrial processes through engineering controls (water and ventilation).

Q6: I am doing a DIY kitchen. Can I cut quartz myself?

It is highly discouraged. Without industrial-grade wet saws and proper respiratory protection (fit-tested respirators, not just N95 dust masks), cutting quartz poses a health risk. Furthermore, quartz is heavy and brittle until installed; professional fabrication ensures the slab doesn’t crack during the cut. Leave fabrication to professionals with the right equipment.

Conclusion

The evolution of the countertop industry toward low silica quartz countertops and enhanced safety protocols is a positive step for workers, the environment, and the industry at large. It represents a maturation of manufacturing—moving toward products that are just as beautiful and durable, but safer to produce.

As a homeowner, you do not need to fear the surfaces in your home. Your kitchen counter is not a hazard to your family. Instead, you can use this knowledge to drive positive change in your community.

By choosing materials responsibly and vetting your fabricators for engineered stone safety compliance, you ensure that your beautiful new kitchen is built on a foundation of ethical labor practices and health awareness. Whether you choose a new low-silica mineral surface, a sintered stone, or a classic granite, the peace of mind comes from knowing you asked the right questions.

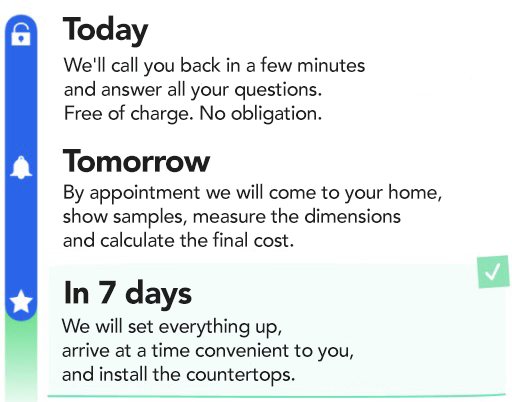

Ready to start your project with a safety-conscious team?

Don’t guess about safety standards. Talk to a professional fabricator who prioritizes worker health and precision installation to ensure your home is safe and beautiful.