Stone fabrication, a blend of art and engineering, has been a cornerstone of architectural and artistic expression for millennia. From the grandeur of ancient pyramids to the intricate carvings in medieval cathedrals, stone has been a medium through which civilizations have showcased their highest achievements. Today, as we stand on the threshold of a new era in stone fabrication, it’s essential to look back at its rich history and understand how its evolution is shaping its future.

Historical Overview of Stone Fabrication

The story of stone fabrication is as old as civilization itself. Early humans used natural stones for tools and shelter, gradually mastering techniques to shape and carve them. This journey from rudimentary shaping to creating complex structures and detailed sculptures is a testament to human ingenuity and creativity. Across cultures and ages – from the Egyptian pyramids to the Greek Parthenon, from the Roman Colosseum to the Taj Mahal – stone has been the canvas for architectural marvels.

The Evolution of Stone Cutting and Shaping Techniques

The transformation in stone fabrication techniques over centuries has been remarkable. In the past, artisans relied on simple tools like hammers and chisels, and the process was labor-intensive and time-consuming. The introduction of the water wheel in the Middle Ages, and later the steam engine, brought in the first wave of mechanization, significantly changing how stone was cut and shaped. The 20th century saw the advent of electrically powered tools, bringing greater precision and efficiency.

As we transition into the 21st century, the stone fabrication industry is undergoing another significant shift. This time, it’s driven by digital technologies. Computer Numerical Control (CNC) machines, laser cutters, and waterjets are not just tools; they represent a new philosophy in stone fabrication. These technologies have not only enhanced precision and efficiency but have also opened up new realms of creativity and design possibilities.

As we continue to explore the future of stone fabrication in this article, it’s important to remember that this journey is not just about technological advancements. It’s about carrying forward a legacy, a craft that has been an integral part of human civilization’s growth and expression. The future of stone fabrication, buoyed by emerging technologies and techniques, promises to continue this legacy, blending the best of our past with the possibilities of the future.

Revolutionizing Stone Cutting: Advanced Machinery

The realm of stone fabrication is undergoing a transformative era, primarily driven by advanced machinery that has revolutionized stone cutting and shaping. This section delves into the impact of high-precision CNC machines and the innovations in waterjet cutting technology, illustrating how they are redefining efficiency and precision in stone fabrication.

High-Precision CNC Machines

The introduction of Computer Numerical Control (CNC) machines in stone fabrication marked a pivotal moment in the industry. These sophisticated machines use computerized controls to manage cutting and shaping tools, bringing a level of precision that was previously unattainable. CNC technology allows for intricate designs to be executed with razor-sharp accuracy, ensuring that each cut is consistent and precise.

One of the most significant advantages of CNC machines is their versatility. They can perform a variety of tasks, from drilling and profiling to routing and polishing, all with meticulous control. This multifunctionality not only saves time but also reduces the risk of errors that can occur when transferring materials between different machines.

Another benefit of CNC technology is its ability to work with digital designs. Artisans and designers can create detailed models on computer software and directly translate them into physical stone pieces. This integration of digital design with physical fabrication opens up new avenues for creativity, allowing for the production of complex and detailed artwork that was once considered too challenging to achieve manually.

Innovations in Waterjet Cutting Technology

Waterjet cutting technology is another groundbreaking advancement in stone fabrication. This method uses a high-pressure stream of water, often mixed with abrasive particles, to cut through stone. The precision and versatility of waterjet cutters have made them an indispensable tool in modern stone fabrication.

The key strength of waterjet cutting lies in its ability to cut through stone without generating heat, thereby eliminating the risk of thermal damage to the material. This feature is particularly beneficial when working with delicate stones or intricate designs that require a gentle touch.

Moreover, waterjet cutters are capable of producing complex shapes and curves with remarkable accuracy. They can easily handle materials of varying thickness and density, making them suitable for a wide range of stone fabrication projects. From creating fine inlays and detailed architectural elements to cutting large slabs for construction, waterjet technology has significantly expanded the capabilities of stone fabricators.

In conclusion, the advent of advanced machinery like CNC machines and waterjet cutters has not only enhanced the efficiency and precision of stone cutting but also unlocked new creative possibilities. These technologies have revolutionized traditional stone fabrication methods, setting a new benchmark for what can be achieved in this timeless craft.

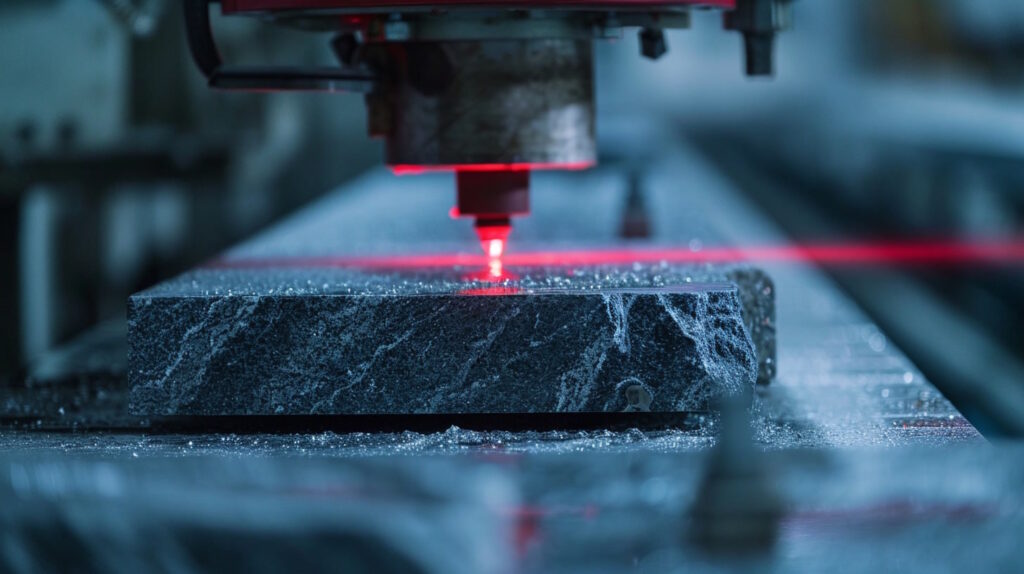

Laser Technology in Stone Fabrication

In the evolving landscape of stone fabrication, laser technology stands out as a beacon of innovation, offering unprecedented precision and efficiency. This section explores the role of laser cutting and engraving in stone fabrication, highlighting how these methods are adding a new dimension of artistic value to stone.

Precision and Efficiency through Laser Cutting

Laser cutting technology has revolutionized the way we approach stone fabrication. By harnessing the power of focused light beams, laser cutters can slice through stone with extraordinary precision. This technology is particularly useful for creating intricate patterns and detailed work that would be challenging, if not impossible, to achieve with traditional cutting methods.

The precision of laser cutting is not its only strength; it also excels in terms of efficiency. The process is significantly faster than conventional methods, reducing production times and allowing for quicker project turnovers. Additionally, the non-contact nature of laser cutting minimizes the wear and tear on tools, leading to lower maintenance costs and extended equipment lifespans.

Laser Engraving: Adding Artistic Value to Stone

Laser engraving has opened up new avenues for artistic expression in stone fabrication. This technique involves using lasers to etch designs onto the surface of stone, allowing for a level of detail that is unparalleled. From intricate graphics and texts to elaborate images, laser engraving can transform a simple stone surface into a work of art.

The versatility of laser engraving is one of its most compelling attributes. It can be used on various types of stone, including granite, marble, and slate, each offering a unique canvas for the artist’s vision. The ability to precisely control the depth and intensity of the engraving means that each piece can be customized to the exact specifications of the client or designer.

Moreover, laser engraving is not just limited to decorative purposes. It has practical applications as well, such as creating signage, memorials, and architectural elements that require both durability and aesthetic appeal.

In conclusion, laser technology has become an indispensable tool in the arsenal of modern stone fabricators. It provides a combination of precision, efficiency, and artistic freedom, pushing the boundaries of what can be achieved in stone fabrication. As this technology continues to evolve, it promises to bring even more exciting possibilities to the world of stone craftsmanship.

3D Printing and Stone Fabrication

The integration of 3D printing technology into stone fabrication represents a groundbreaking intersection of ancient material and modern innovation. This section explores how 3D printing is influencing stone construction and design, along with its potential in crafting intricate stone structures.

Combining Ancient Material with Modern Technology

3D printing, also known as additive manufacturing, involves creating objects by layering material based on digital models. In stone fabrication, this technology is opening new frontiers, allowing for the creation of structures and designs that were previously impossible or prohibitively expensive to produce using traditional methods.

One of the most significant benefits of 3D printing in stone fabrication is its ability to produce complex geometries with a high degree of precision. This capability is particularly valuable in architectural applications, where custom, intricate designs are often required. 3D printing facilitates the creation of these unique shapes and textures in stone, offering architects and designers unparalleled creative freedom.

Case Studies: 3D Printed Stone Structures

There are several notable examples of how 3D printing is being used to create innovative stone structures. These case studies not only demonstrate the practical applications of 3D printing in stone fabrication but also highlight the technology’s potential to transform the industry.

One such example is the use of 3D printing to produce lightweight stone panels. These panels can be used in façades and interior designs, offering the beauty and durability of stone without the traditional weight constraints. This application is particularly beneficial in retrofitting older buildings or in designs where weight is a critical factor.

Another exciting development is the use of 3D printing for creating intricate stone sculptures and artistic installations. Artists and sculptors are leveraging this technology to push the boundaries of their craft, creating pieces that would be extremely difficult, if not impossible, to carve by hand.

In conclusion, 3D printing technology is proving to be a valuable tool in the realm of stone fabrication. It not only enhances the efficiency and precision of creating stone structures but also inspires innovation and creativity. As this technology continues to mature, its impact on stone fabrication is expected to grow, paving the way for even more remarkable applications in the future.

Global Trends in Stone Fabrication

The stone fabrication industry, much like any other, does not exist in isolation but is influenced by global trends and market dynamics. This section examines how international developments, cultural influences, and technological advancements are shaping the stone fabrication landscape across the world.

The Influence of Global Markets on Stone Design

Globalization has had a profound impact on the stone fabrication industry. The exchange of ideas and techniques across borders has led to a fusion of styles and preferences, resulting in a more diverse range of stone products. For instance, the demand for exotic stones from different parts of the world has increased, leading to a broader spectrum of materials available to fabricators and designers.

Moreover, international trade agreements and the global supply chain play a significant role in determining the types of stone that are readily available in various markets. These factors often influence trends in stone usage, with certain materials becoming more popular due to their availability and cost-effectiveness.

Case Studies: International Stone Fabrication Projects

Examining international stone fabrication projects offers insights into how different cultures and regions approach stone design and construction. For example, in Europe, there is a strong preference for preserving historical architecture, which influences the techniques and materials used in stone restoration projects. In contrast, regions like the Middle East and Asia are experiencing a boom in modern construction, leading to innovative uses of stone in contemporary architecture.

These case studies not only highlight the diverse applications of stone but also showcase how local regulations, environmental conditions, and cultural aesthetics influence stone fabrication practices around the world.

Technological Exchange and Collaboration

The global nature of the stone fabrication industry has facilitated technological exchanges and collaborations between countries. Innovations developed in one part of the world are rapidly adopted elsewhere, leading to a more interconnected and advanced industry. For instance, Italian stone cutting machinery, renowned for its precision and quality, is used worldwide, while advancements in digital templating and design software in the US and Europe are influencing stone fabrication techniques globally.

In conclusion, global trends in stone fabrication are characterized by a blend of cultural influences, technological advancements, and market dynamics. These factors collectively shape the future of the industry, driving innovation and fostering a rich diversity in stone design and applications.

Challenges and Solutions in Modern Stone Fabrication

As the stone fabrication industry strides forward, embracing new technologies and methodologies, it inevitably encounters a set of challenges. Addressing these challenges is crucial for the sustainable growth and evolution of the industry. This section outlines some of the primary challenges faced in modern stone fabrication and the innovative solutions being developed to overcome them.

Addressing Environmental Concerns

One of the significant challenges in stone fabrication is its environmental impact. The process of quarrying and transforming stone into finished products can be resource-intensive and may lead to significant waste. Furthermore, the transportation of stone, often across great distances, adds to the carbon footprint of the industry.

In response, the industry is increasingly focusing on sustainable practices. This includes recycling and reusing stone waste, using water more efficiently in cutting processes, and implementing quarrying practices that minimize environmental disruption. Additionally, there is a growing trend towards using local stone materials where possible, reducing transportation emissions.

Overcoming Technical Limitations in Stone Cutting

Despite advancements in technology, certain technical limitations still exist in stone cutting, particularly when working with complex designs or particularly hard materials. Traditional methods can be time-consuming and may not always achieve the desired precision.

To address these issues, continuous innovation in machinery and techniques is essential. For instance, advancements in diamond cutting technology have made it possible to cut harder stones more efficiently. Similarly, the integration of AI and machine learning in stone fabrication equipment is improving precision and reducing waste by optimizing cutting paths and predicting potential faults in the material.

Balancing Tradition with Innovation

An ongoing challenge in the stone fabrication industry is balancing the preservation of traditional craftsmanship with the adoption of modern technologies. While technological advancements offer efficiency and precision, there is a concern about losing the artistry and unique qualities that come with traditional handcrafted methods.

The solution lies in finding a harmonious integration of technology and tradition. This can be achieved by using modern tools and techniques to enhance rather than replace traditional skills. For example, digital templating can be used to plan a project, while the final touches are applied by skilled artisans, ensuring that each piece retains its unique handmade quality.

In conclusion, the challenges faced by the modern stone fabrication industry are varied and complex. However, through innovation, a focus on sustainability, and a respect for traditional craftsmanship, these challenges can be transformed into opportunities for growth and development.

Consumer Perspective: Demand and Expectations

In the dynamic landscape of stone fabrication, understanding consumer perspectives is vital for the industry’s growth and adaptation. This section delves into the evolving demands and expectations of consumers in relation to stone products and services, providing insights into how the industry can better align with these trends.

How Consumer Trends are Shaping Stone Fabrication

Consumer preferences play a crucial role in shaping the products and services offered by the stone fabrication industry. In recent years, there has been a noticeable shift towards personalized and bespoke stone products. Consumers are increasingly seeking unique designs, custom sizes, and specific finishes that reflect their individual style and the architectural character of their spaces.

This trend towards customization has driven fabricators to adopt more flexible and versatile production methods. Advanced technologies such as CNC machines and waterjet cutters are particularly valuable in this context, as they allow for precise and custom cutting of stone to meet individual specifications.

The Growing Demand for Customized Stone Products

The desire for customized stone products extends beyond just personal preferences. It also reflects a broader interest in sustainable and eco-friendly materials. Consumers are more conscious of the environmental impact of their choices and are often willing to invest in high-quality, durable stone products that are sourced and fabricated responsibly.

To meet this demand, stone fabricators are exploring the use of locally sourced materials, which not only reduce the carbon footprint associated with transportation but also offer a sense of local authenticity and charm. Additionally, the industry is seeing a growing interest in reclaimed and recycled stone, appealing to environmentally conscious consumers.

Adapting to Changing Consumer Needs

The stone fabrication industry must remain agile and responsive to these changing consumer needs. This involves not only adopting new technologies and sustainable practices but also ensuring excellent customer service and communication. Educating consumers about the benefits and characteristics of different types of stone, as well as the intricacies of the fabrication process, can help them make more informed decisions and appreciate the value of custom stone work.

In conclusion, the consumer perspective in the stone fabrication industry is characterized by a desire for customization, quality, and sustainability. By understanding and responding to these demands and expectations, the industry can continue to thrive and grow, offering products and services that resonate with modern consumers.

Conclusion

The journey through the landscape of modern stone fabrication reveals an industry at the crossroads of tradition and innovation. From the precision of CNC machines to the artistic possibilities offered by laser technology, from the groundbreaking potential of 3D printing to the influence of global trends, stone fabrication is an industry in transformation.

Summarizing the Future Outlook of Stone Fabrication

The future of stone fabrication is bright and promising. As we have explored, the industry is not only adopting new technologies but also reviving traditional craftsmanship, creating a unique blend of the old and the new. The increasing demand for customized and sustainable stone products is driving innovation, pushing the boundaries of what can be achieved with this age-old material.

The Interplay of Tradition and Innovation in Stone Working

The key to the future success of the stone fabrication industry lies in its ability to balance tradition with innovation. While embracing advanced technologies and sustainable practices, it’s crucial to preserve the artisanal skills that give stone its timeless appeal. This interplay between the past and the present is what will continue to drive the industry forward, catering to a market that values both technological advancement and craftsmanship.

As we look ahead, the stone fabrication industry is poised to continue its evolution, shaped by technological advancements, consumer preferences, and global trends. It stands as a testament to human ingenuity and creativity, continuing to push the limits of architectural and artistic expression through stone.